Have you ever seen an orthosis fail even though every component looked right?

In many cases, the issue is not the joint itself but how it was aligned during fabrication. Small alignment errors can lead to discomfort, reduced durability, or poor gait mechanics.

We explain why orthotic joint alignment matters, how top and bottom positioning affects performance, and what clinicians and technicians can do to avoid common mistakes that compromise function.

Why Alignment Is the Foundation of Joint Performance

Alignment sets the stage for how an orthotic joint behaves under load. When the joint sits correctly within the orthosis, movement feels controlled and predictable. When it doesn’t, problems show up fast. You may see uneven wear, unexpected resistance, or discomfort during stance and swing.

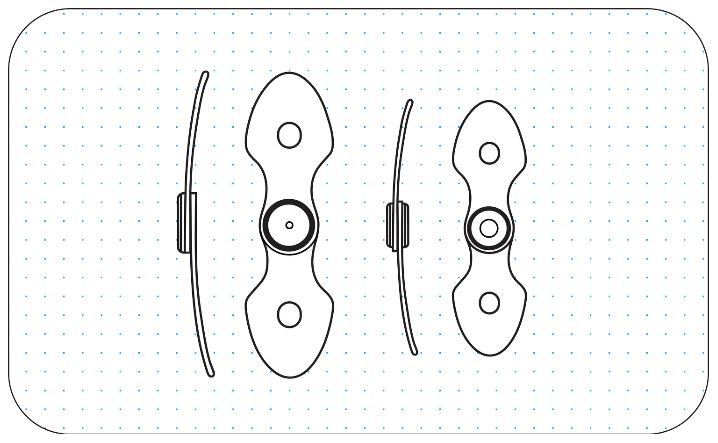

Top and bottom alignment refers to how the hinge plates or joint components are positioned relative to each other within the orthotic shell. If one plate sits higher or rotates differently, motion no longer follows the intended axis. Instead of guiding the ankle, the joint begins to fight it.

This is why orthotic joint top-bottom alignment affects more than aesthetics. It influences sagittal motion, load transfer, and long-term joint integrity. Proper alignment ensures that forces move through the orthosis evenly, reducing stress on the plastic shell and surrounding anatomy.

Clinicians often focus on component selection. Yet alignment determines whether that component performs as designed.

What Happens When Top-Bottom Alignment Goes Wrong

Misalignment rarely fails immediately. Instead, it causes subtle issues that grow over time.

A common problem is uneven cavity fit. If the top plate sits proud while the bottom plate sinks deeper, the joint experiences uneven stress. This leads to loosening, noise, or cracking around the hinge area.

Another issue is rotational mismatch. When hinge plates are reversed after vacuum forming, one side may fit well while the other binds. This creates friction during motion and increases wear.

Gait deviations also appear. Users may feel resistance during tibial progression or instability during push-off. Over time, compensatory movement at the knee or hip may develop.

Many of these failures trace back to orthotic joint top-bottom alignment errors made early in fabrication. Once embedded, they are difficult to correct without rebuilding the device.

Fabrication Practices That Protect Alignment Accuracy

Alignment starts before the plastic is heated. It begins with how the joint is placed on the positive model.

- Use fixation points consistently. Securing the joint to the model prevents shifting during vacuum forming. This keeps the axis true.

- Cavity preparation matters. The cavity should match the joint profile closely. A loose cavity allows rotation. A tight cavity supports stability.

- Orientation must stay consistent. If hinge plates overlap in a specific direction during forming, they must be reinstalled the same way after trimming. Reversal introduces uneven spacing and poor fit.

- Thin interface materials help. Using minimal nylon over the joint improves cavity definition and prevents excess material buildup that alters alignment.

- Alignment errors are often invisible until the orthosis is worn. Careful fabrication prevents that outcome.

How Proper Alignment Improves Clinical Function

Correct alignment does more than protect the joint. It improves how orthosis works with the body.

When the joint axis aligns with anatomical motion, the ankle moves smoothly. Sagittal control becomes predictable. Resistance feels intentional rather than restrictive. Proper alignment also reduces medial-lateral deformation. This matters when motion limiters or tension systems are added. A well-aligned joint supports these components instead of amplifying stress.

From a patient perspective, comfort improves. Shoes fit better. Movement feels natural. Fatigue decreases. Clinicians benefit as well. Fewer adjustments. Fewer returns. More consistent outcomes across patients. Understanding orthotic joint top-bottom alignment allows teams to build orthoses that perform reliably over time.

Practical Alignment Checks Before Final Delivery

Before delivering an orthosis, alignment should be verified. These checks prevent post-fit issues.

- Confirm that both hinge plates sit flush within the shell

- Check for smooth motion through the full ankle range

- Inspect for uneven gaps or binding

- Verify orientation matches fabrication setup

- Observe gait for unexpected resistance

These steps take minutes. Yet they save hours of rework. Alignment is not a single step. It is a process that runs from model preparation through final fitting.

Long-Term Durability Depends on Alignment

Durability is often blamed on materials. In reality, alignment plays an equal role. Even strong joints fail when stressed unevenly. Misaligned components concentrate force at specific points. Over time, this leads to loosening or cracking.

Aligned joints distribute load evenly. Movement stays centered. Fasteners hold longer. The orthosis maintains integrity.

This becomes even more important for active users. Repeated cycles magnify small errors. Proper alignment prevents early breakdown and extends device lifespan.

FAQ

- Why is top-bottom alignment important in orthotic joints?

Alignment ensures the joint moves along its intended axis. Poor alignment creates uneven stress and affects gait quality.

- Can alignment issues cause discomfort?

Yes. Misalignment can lead to resistance, rubbing, or instability during walking.

- How can technicians prevent alignment errors?

Consistent orientation, secure fixation, and tight cavity preparation help maintain accuracy.

- Does alignment affect joint durability?

Absolutely. Even durable materials fail faster when forces are unevenly distributed.

- When should alignment be checked?

Alignment should be reviewed during fabrication, after trimming, and before final delivery.

The Final Words

Orthotic joints perform best when alignment is treated as essential, not optional. Proper positioning protects the joint, supports natural movement, and improves patient comfort. Small details during fabrication shape long-term outcomes.

By focusing on orthotic joint top-bottom alignment from the start, clinicians and technicians can deliver devices that work as intended and last longer in real-world use.

If you want orthotic joints that move smoothly and stay reliable, alignment deserves your full attention every step of the way.